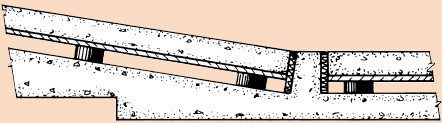

TYPICAL SLOPED THEATRE FLOOR

LDS FORM-WORK SYSTEM FOR TV STUDIOS, THEATRES, BOWLING ALLEYS, KITCHEN, SQUASH COURTS, EXERCISE ROOMS, ETC.

1.01 Description

- Scope of Work

- Isolate floating floors from building structure by means of LDS isolators under plywood panels and perimeter isolation in mechanical equipment rooms as shown on the drawings.

If sound barrier walls are used, add the following: - Build sound barrier walls on the floating floors.

- Isolate floating floors from building structure by means of LDS isolators under plywood panels and perimeter isolation in mechanical equipment rooms as shown on the drawings.

- Substitution of Materials

- Substitute materials shall meet or exceed the “quality” of the products which are listed in these Specifications. Submit samples and test reports by an independent laboratory for consideration on this project.

1.02 Design

- Intent

- The floating floor shall consist of a 4”(100mm) thick concrete slab isolated from and supported 21/2”(62mm) above the waterproofed structural slab by resilient LDS isolators covered by plywood panels that form the pouring surface. If sound barrier walls are used, add the following:

Sound barrier walls consisting of 6” (150mm) filled concrete block (Barrier wall construction may be changed by architect when writing specification) shall rest on the floating floor with a 31/2”(90mm) air gap to the structural walls. (31/2”(90mm) may be reduced to 2”(50mm) if no sway braces are needed.) - The floating floor slab shall be isolated from adjoining walls and curbs by means of perimeter isolation.

- Any floor drains, piping, conduit and duct penetrations must not short circuit the isolation system.

- Any equipment within these rooms shall be mounted on housekeeping pads or directly on the floating floor as shown on the drawings.

- Any equipment within these rooms shall be mounted on housekeeping pads or directly on the floating floor as shown on the drawings.

- In seismic zones the floating floor shall be restrained horizontally by curbs or walls designed to withstand the horizontal seismic forces. Solid bridge bearing LDS pads shall be interspersed between perimeter isolation to withstand the seismic forces with a maximum deflection of 0.2”(5mm). When perimeter cannot be used for seismic constraint, intersperse horizontal restraints within floor system.

- The floating floor shall consist of a 4”(100mm) thick concrete slab isolated from and supported 21/2”(62mm) above the waterproofed structural slab by resilient LDS isolators covered by plywood panels that form the pouring surface. If sound barrier walls are used, add the following:

- Performance Requirements

- The floating floor system shall have a minimum rating of STC-79 and INR+17 as verified by an independent laboratory in prior tests.

- Floor System Construction Procedure

- The setting of all isolation materials shall be performed by or under the supervision of the isolation manufacturer.

- Set and waterproof any drains and lower pipe seals in keeping with waterproofing specifications.

- Cement perimeter isolation around all walls, columns, curbs, etc.

- In seismic zones intersperse the perimeter isolation with bridge bearing quality LDS pads the thickness of the perimeter isolation.

- Place individual LDS isolators on the sub-floor at a maximum spacing of 24” (600mm) in strict accordance with the approved drawings prepared by the isolation manufacturer. Additional reinforcement must be detailed on isolation manufacturer’s drawings when required.

If sound barrier isolation walls are used, add the following:

Perimeter isolators shall be selected to support the wall weight in addition to the perimeter of the floating floor. - Cover isolators with 1/2”(12mm) AC plywood. Isolators shall be located under joints and joints staggered. Connect plywood at abutting edges with plywood junction plates.

- Cover the plywood with polyethylene sheeting and carry it up the walls past the perimeter isolation.

- Place reinforcing as shown on the drawings and pour floor monolithically.

- After the concrete has hardened, caulk all perimeter isolation.

If sound barrier walls are used, add 9. - Construct block walls on the floating floor being careful that mortar does not drop behind the walls. Place 2”(50mm) fiberglass bats against the structural wall as a precaution. Provide sway braces and isolated angle iron wall braces at the top of the walls. Caulk angle iron braces.

- Submittals

- Detailed product drawings and load /deflection curves of all isolators.

- AASHTO Test Reports on all properties in table 2.01 A from an accredited independent laboratory for all rubber durometers used.

- Dynamic stiffness test from an accredited independent laboratory at 5, 10 and 15 Hz, showing dynamic stiffness does not exceed 1.4.

- Isolation frequency not to exceed 9 Hz at stated deflection.

- Acoustical test data from an independent laboratory showing a minimum STC-79 and a minimum INR+17 using a 4”(100mm) concrete floating floor, a 6”(150mm) structural floor and 2”(50mm) air gap.

- A drawing or drawings showing:

- Dead, live and concentrated loads.

- Isolators sizes, deflections, frequencies and locations.

If sound barrier walls are used, add the following:

Wall sway brace and isolator, angle iron brace sizes, locations and frequencies. - Any drain and penetration locations.

- Size type elevation and spacing of concrete reinforcement.

- Caulking details.

- Floating floor and wall construction procedure.

1.03 Quality Assurance

- Floating floor system components shall be designed and fabricated by a manufacturer with at least ten years experience in one hundred similar installations.

- The floating floor isolation materials and panel board forms shall be installed under the supervision of the isolator manufacturer.

1.04 Site Conditions

- If site conditions are unsatisfactory or raise questions about the installation of the floating floor, the work will not proceed until the condition has been corrected in a manner acceptable to the isolation manufacturer.

1.05 Sequencing and Scheduling

Coordinate work with other trades and coordinate scheduling with the construction supervisor to minimize delays.

2.01 Isolators

- Cylindrical LDS mountings with a diameter no less than 0.9 of the 2”(50mm) height. Isolators are molded to the following LDS AASHTO bridge bearing specification. Maximum durometer 60. Deflections shall not exceed 0.3”(7.5mm) nor the frequency 10Hz. Isolators shall be Mason Industries Type EAFM.

AASHTO Bridge Bearing Specifications for Polyisoprene ORIGINAL PHYSICAL PROPERTIES TESTED FOR AGING COMPRESSION SET ASTM D-395 22hrs/158°F Method B LONG TERM CREEP ISO8013 168 hrs Tests: Tests: ASTM D-2240 & D-412 OVEN AGING(70hrs/158°F)

ASTM D-573OZONE

ASTM D-1149ASTM D-395 ISO8013 Durometer Shore A Tensile Strength (min) Elongat. at Break (min) Hardness (max) Tensile Strength (max) Elongat. at Break (max) 25 pphm in air by Vol. 20% Strain 100°F 22hrs/158°F Method B 168 hrs 40±5 2000 psi 500% +10% -25% -25% No Cracks 25%(max) 5%(max) 50±5 2250 psi 450% +10% -25% -25% No Cracks 25%(max) 5%(max) 60±5 2250 psi 400% +10% -25% -25% No Cracks 25%(max) 5%(max) 70±5 2250 psi 300% +10% -25% -25% No Cracks 25%(max) 5%(max) NOTE: 40 Durometer is not included in AASHTO Specifications. Numbers are Mason standard

If sound barrier walls are used, add the following:

- Wall Sway Braces: Double acting LDS sway braces with a fail safe feature in three planes. Braces shall be furnished with a bracket for bolting to the structural wall and a hooked end for insertion in the masonry joint. Braces shall have a frequency not in excess of 10Hz based on the weight of the wall area per brace and a vertical stiffness not in excess of 50% of the horizontal. Sway Braces shall be Mason Industries Type DNSB.

- Angle Brackets: 11/2”(40mm) x 2”(50mm) angle iron sections with provision for bolting to the structure and a minimum thickness of 3/8”(9mm) sponge cemented to the vertical leg. Angle Brackets shall be Mason Industries Type AB-716.

2.02 Bond Breaker Material

- Provide one (1) layer of 6 mil (0.15mm) polyethylene sheeting

2.03 Perimeter Isolation

- Minimum 3/4”(20mm) thick PVC foam, density 7 lbs/ft3 average. PVC foam shall be Mason Industries P7.

- In seismic zone perimeter isolation shall be interspersed with 3/4”(20mm) thick, 60 durometer LDS bridge bearing pads the height of the perimeter material. Bridge bearing pad shall be made to the same AASHTO specifications, as shown for the EAFM mountings and sized for a maximum deflection of 0.2”(5mm) at maximum earthquake forces. Interspersed pads shall be Mason Industries Type LDS-BBP.

2.04 Perimeter Caulking Compound

- Non-hardening, drying or bleeding. Troweling or pouring grade. Caulking compound shall be Mason Industries Type CC-75.

2.05 Floating Floor Drains

- Cast iron design. The upper funnel section cast into the floating floor. Lower bucket, built into the structure, shall retain water surrounding the upper section as a between floors sound seal. Weep holes are required to drain the structural floor. Floor drains shall have water proofing membrane clamps. Floor drains shall be Mason Industries Type CFD-18591.

2.06 Plywood

- Type AC exterior grade 1/2”(12mm) thick.

3.01 Installation

Install the floating floor systems according to the installation and adjustment procedures and drawings submitted by the isolator manufacturer and approved by the architect.